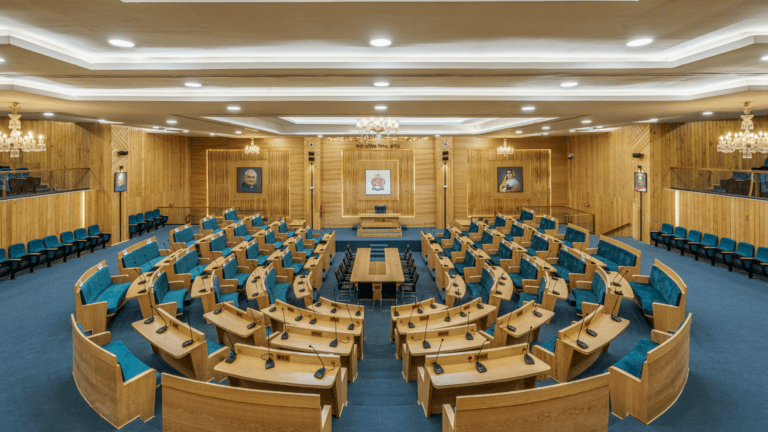

Photos: FII Vietnam

As interest in softwoods from British Columbia (BC) continues to increase, there is growing opportunity for technical support to facilitate adoption

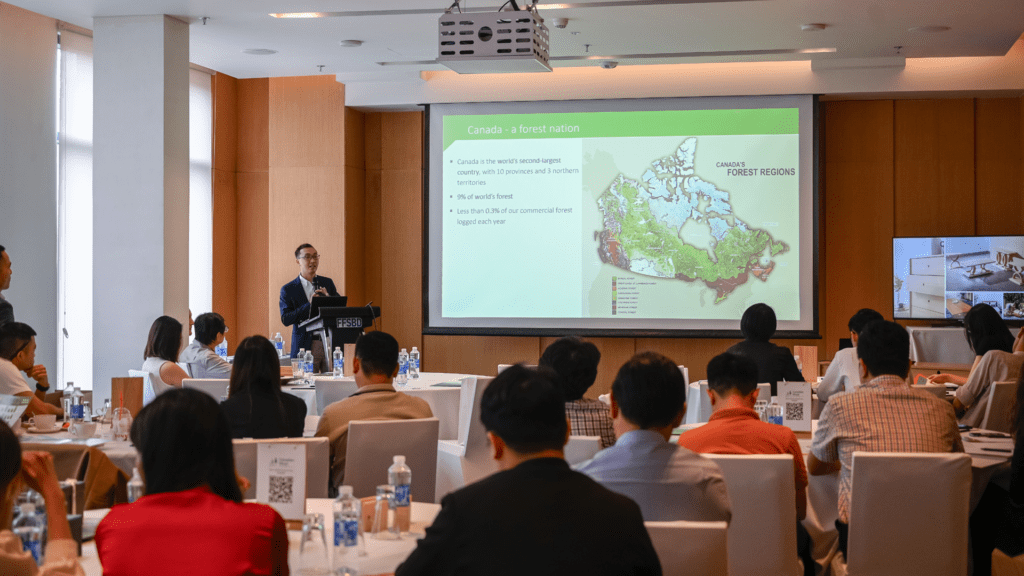

More and more furniture manufacturers are looking to BC softwood species as an alternative to hardwood in their production processes. As interest grows, so does the demand from manufacturers in Vietnam for more detailed technical advice. In a continuing effort to bridge knowledge gaps in support of this transition, FII Vietnam held a successful seminar on best practices with BC wood species. As Vietnam’s furniture manufacturing industry is becoming familiar with the wood products from BC, this seminar delved deeper into more technical aspects of working with the wood.

Vietnam’s value-added wood products manufacturing has far outpaced the growth of domestic wood supply. With this comes an increasing demand for legal, sustainable and certified sources of wood. Combined with decreased supply of some commonly used hardwoods, softwood species from British Columbia are increasingly being recognized as a suitable alternative.

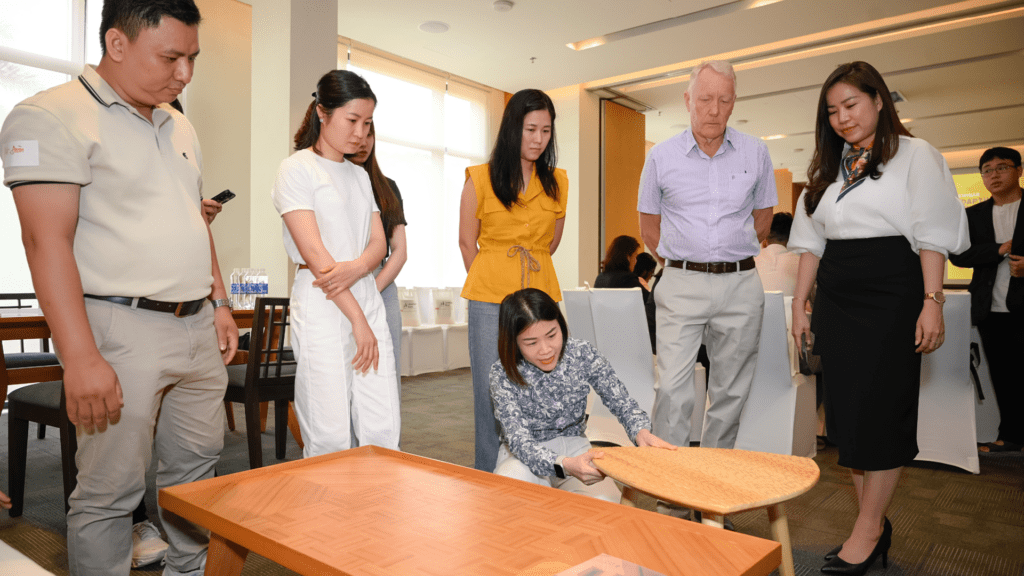

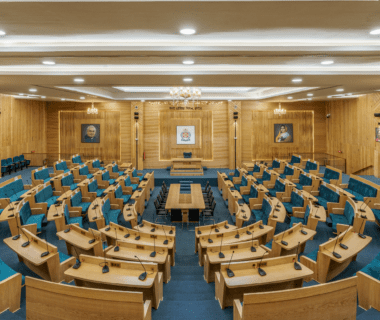

The seminar, “Best Practices – Adapting New Wood Species in Your Production,” brought together manufacturers, experts, and industry leaders to explore the unique properties and benefits of sustainable wood from BC. Attendees were impressed by the materials’ strength, durability, and versatility, which make it ideal for a wide range of furniture applications.

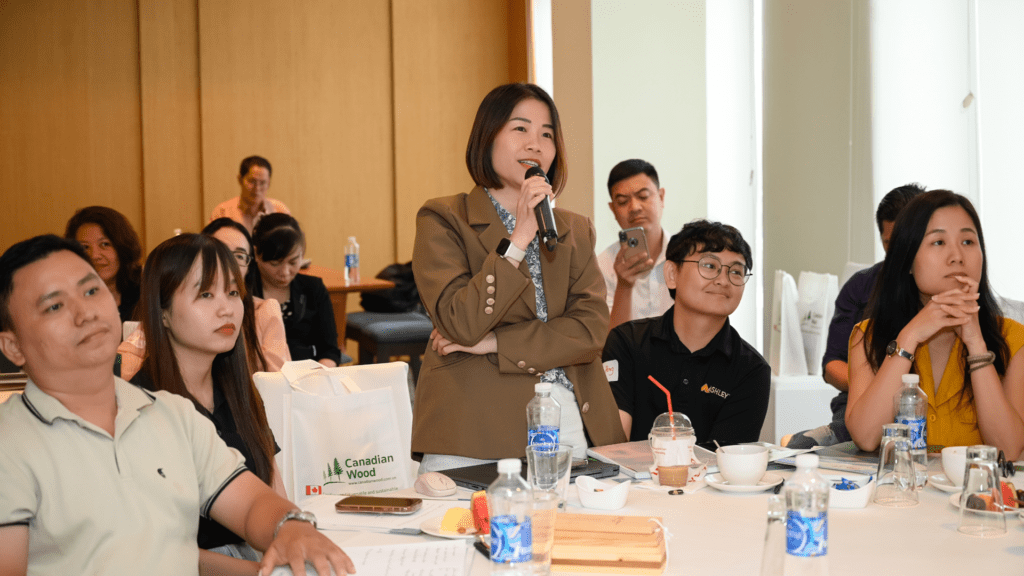

Through detailed sessions led by FII Vietnam’s technical team, the seminar delved into various manufacturing topics, such as addressing industry challenges like warping, moisture content, mechanical failures, machinery adjustments, wood movement, and coating techniques. With a range of small- and medium-sized companies to large-scale manufacturers, the seminar also covered requested topics such as U.S. safety standards, cost-efficiency and improving production processes.

After attending the seminar, many companies registered for the “Try Canadian Wood” product trial program. This program is a low-cost way to encourage key manufacturers to sample BC species in their own production processes, ensuring it meets their specific needs and standards. The technical team in Vietnam provides assistance to the manufacturers to help them understand the properties of BC species and advise them throughout the trial process.

The positive reception to the seminar emphasized the growing demand for sustainable and high-quality wood products in Vietnam. Attendees were particularly interested in technical comparisons between BC species and other commonly used woods. Feedback included requests for more presentations and expressions of interest for collaboration and technical support.

As Vietnam’s furniture industry continues to expand, opportunity for sustainable wood from BC continues to grow to support the demand.