Through the Wood First program, FII helps expand B.C.’s capacity to make value-added wood products and building systems. This added capacity strengthens B.C. as a hub for wood product innovation, ensuring the industry remains at the forefront of sustainable building solutions.

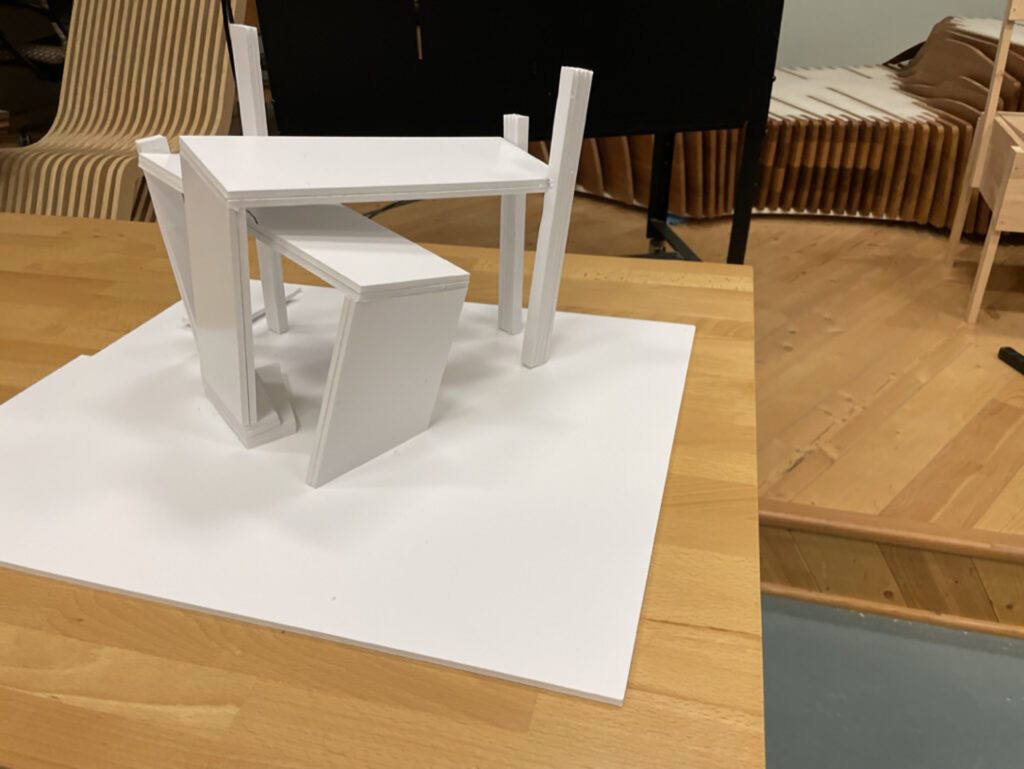

As a relatively new building product in North America, mass timber use still faces knowledge gaps in the design, engineering, manufacturing, and construction sectors. To address this barrier to growth, the University of British Columbia’s Centre for Advanced Wood Processing (CAWP) organized a three-day workshop dedicated to mass timber construction through Design for Manufacturing and Assembly (DfMA). DfMA prioritizes ease of manufacturing and assembly by minimizing time, waste, cost and labor, while improving quality and efficiency.

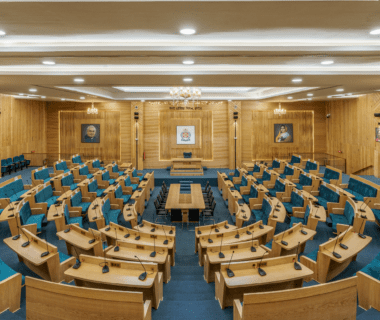

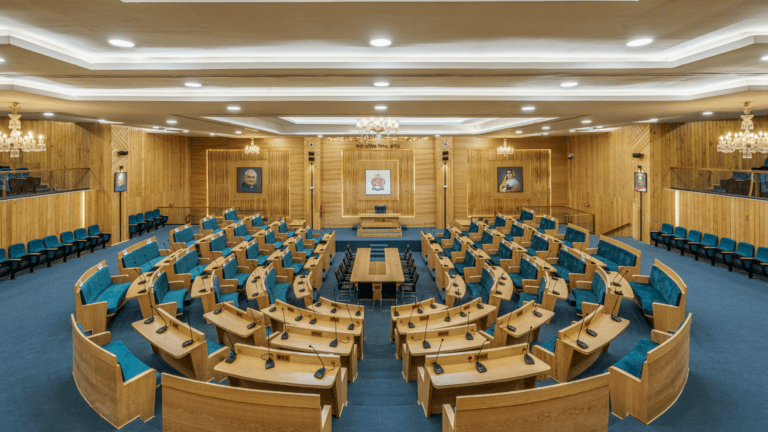

The workshop employed a hands-on lecture/design/build format, attracting designers, engineers, manufacturers, and contractors. Now in its second year, the sold out workshop drew 16 industry participants and three UBC wood product students who collaborated on the design, fabrication, and assembly of a pavilion using cross-laminated timber and glulam beams.

The workshop’s success and the interest it generated indicate a growing acknowledgment of the significance of DfMA in promoting collaboration, reducing costs, and enhancing the efficiency and quality of mass timber construction projects.

Photo: UBC Centre for Advanced Wood Processing

Photo: UBC Centre for Advanced Wood Processing