Market Overview

BC and Canada have a long-standing presence in the Japanese market and are widely recognized as leading players in supplying wood products to Japan’s residential construction sector.

While Japan’s aging population has led to a decline in single-family housing starts, government policies encouraging wood use in hybrid, multi-family/multi-storey, and non-residential construction have opened doors for BC wood products within these segments.

The growing demand for wood pellets and the increasing use of value-added products further enhance the market potential for BC in Japan.

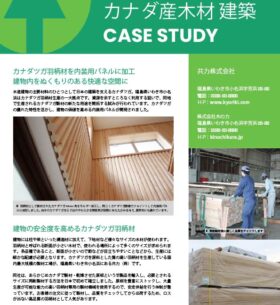

Photo: This is Me | Credit: Fuji Realty Co., Ltd.